No matter what the requirements for the decoration or printing technology are, Addy will try to provide the customer with the right labeling solution which is to align with the customer's needs hierarchy because it is associated with the customer's primary label. This packaging component is often the "face" of the visual brand and the particular most important packaging element. Addy has the expertise of market and resource network to provide you with the best labeling solution. Whether compare the most competitive technology through price to decide the additional functional needs that attract the end-user, or simply increase the visual brand's appeal to attract consumers from the shelves.

1.INCOMING QUALITY CONTROL

For all raw materials purchased, according to the requirements of quality management, Raw materials is inspected, tested, confirmed and recorded by sampling.

A.Initial adhesion tester

B.Tape retentivity tester(persistent adhesion)

2.PRE-PRESS

·Data Driven.

·Color management and layouts in systematic, measureable, deliverables for consistency.

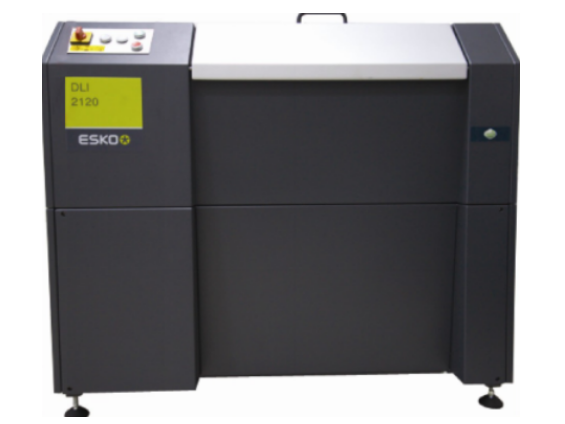

·Advanced ESKO Laser engraving plate making equipment

It avoids all kinds of common problems in the printing process of film imaging, and is beneficial to the stability of the quality of prepress plate making.

3.PROCESS MANAGEMENT (While Printing)

(1) Implementation of the printing initial workpiece,including :

A: inspection of adhesion of printing ink on label surface.Testing equipment for resistance to friction

B:Spray code effect test on label surface,matching the spraying equipment,do spray test before mass production , to see whether vanishing is all right to meet customer's requirement.

(2) Preventive Measure

In order to prevent the precipitation during the storage of varnish, the varnish is fully and evenly stirred before being used on the machine ,to avoid abnormal spraying code on the label surface.

4.QUALITY(After Printing )

·Desired Intent to deliver every order and item 100% on time (Customer Request Date)

·100% inspection twice (First manual inspection, second AVT machine inspection) in full, no errors.

· Comprehensive QA team deliver reliable traceability systems for those markets dependent on this need.

5、QUALITY CONTROL METHOD ON SITE

A.All quality inspection machines shall carry out site-clearing records.

B.For each product, confirm the sampling and implement it when make up the defective label.

C.Fill in the abnormal form of AVT inspection equipment and archive the defective samples as the basis for follow-up traceability.